We provide Roll Forming Machine for global customers

-

ProductsOur products are mainly used in the production of steel structure industry C, Z type sandalwood, floor bearing formwork and roof, wall maintenance structure color board or insulation board; Environmental protection industry dust anode plate, cathode plate;

-

AboutHaide Machinery was founded in 1996. The company is the strength of strong technical strength of cold forming equipment and complete sets of automatic production line manufacturers.

-

NewsThe enterprise has strong technical force, rich manufacturing experience, so that our products can help customers improve efficiency, reduce costs, enhance competitiveness.

-

ServiceOur sales and design staff will listen carefully to your exact requirements and needs to design and manufacture to help you get the most ideal equipment.

Roll Forming Machine Industry

The company is the strength of strong technical strength of cold forming equipment and complete sets of automatic production line manufacturers.

Learn More →

According to Customer Needs

The company is the strength of strong technical strength of cold forming equipment and complete sets of automatic production line manufacturers.

Learn More →PRODUCTS

Choose from Our Feature Products

Haide Machinery was founded in 1996. The company is the strength of strong technical strength of cold forming equipment and complete sets of automatic production line manufacturers.

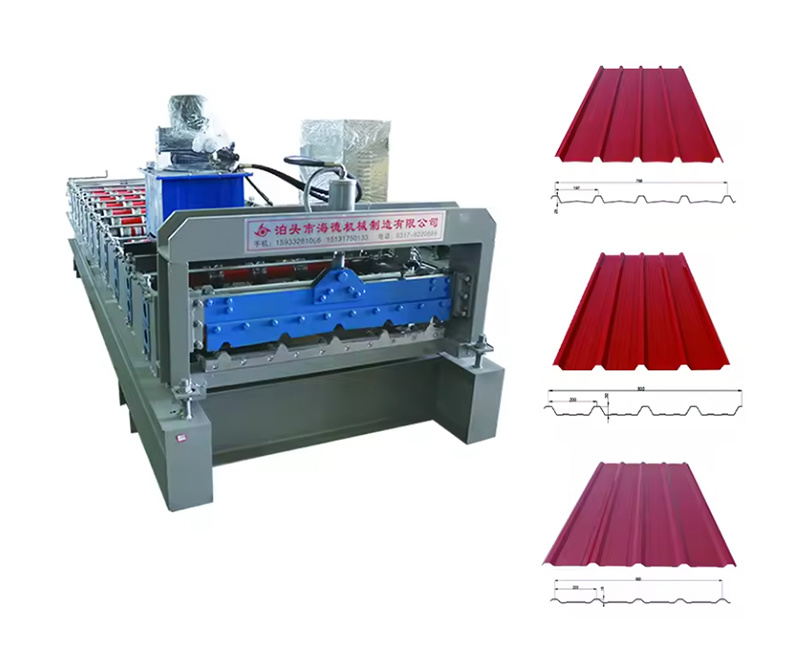

840 veneer roof roll forming machine

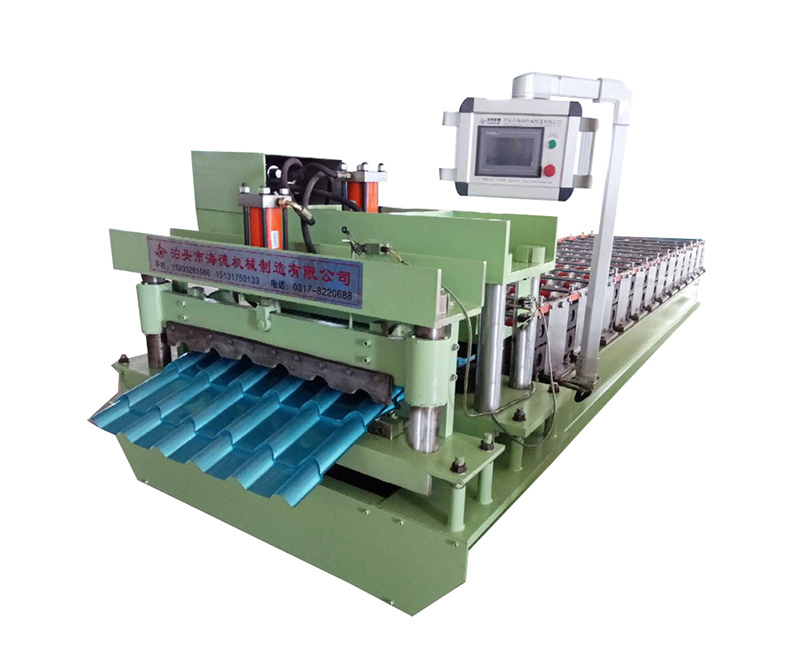

800 Metal Iron Sheet Roof Tile Roll Forming Machine

828 Steel tile forming glazed machine self lock roofing sheet making machine

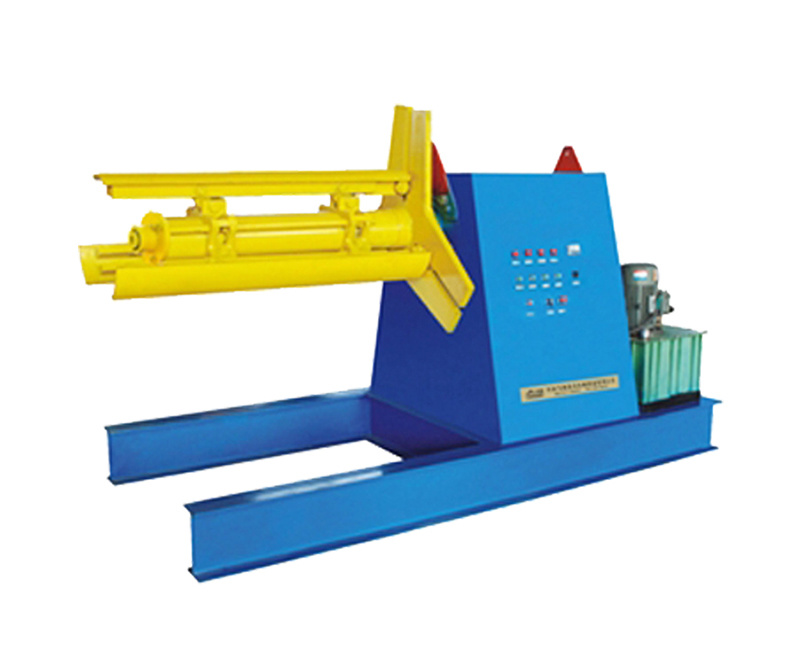

Automatic coiling and unwinding machine with hydraulic unwinding car

760 Roofing Sheet Machine Corrugated Sheet Metal Roof Making Machine

High speed hydraulic automatic unwinding machine

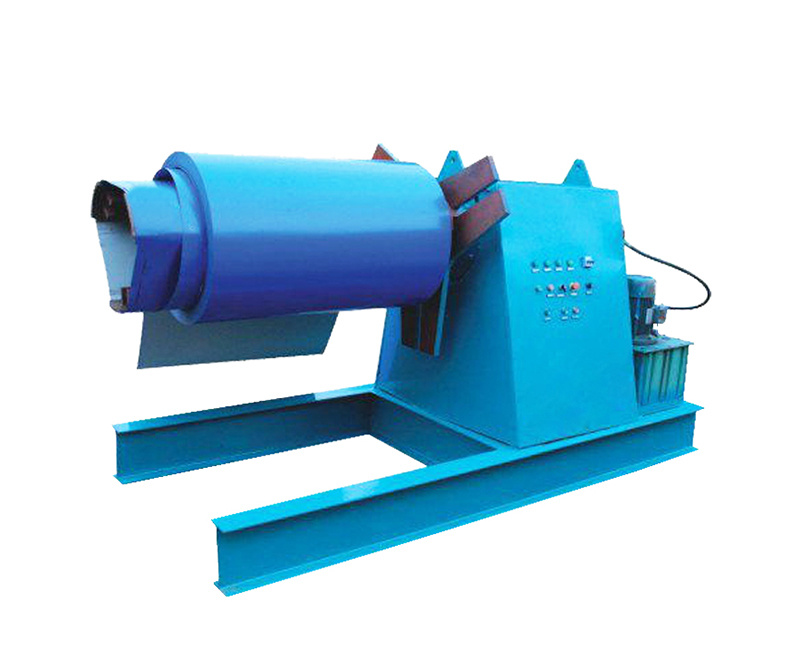

Heavy duty automatic hydraulic unwinding machine with trolley

Aluminium hydraulic Sheet Roll Bending Machine 4-6m color steel sheet bending shearing machine

Galvanized Iron Cutting Leveling Roll Forming Machine Sheet Metal Slitting Machine

Roof tile roller forming machine hydraulic unwinding machine

Automatic sheet metal unwinding machine for rewinding

Automatic Heavy steel coil Hydraulic decoiler & uncoiler

5-ton fully automatic hydraulic unwinding machine

Hydraulic Decoiler Machine Color Steel Unwinding Machine

Fully automatic hydraulic unwinding machine coil machine

Hydraulic High Speed Stainless Steel Coil Uncoil Machine

Automatic hydraulic decoiler steel coil unwinder machine for sheet metal unwinding

1008 High speed corrugated roof panel manufacturing machine, trapezoidal panel forming machine

Decoiler using together with roll forming machine

HAIDE MACHINERY HAIDE MACHINERY HAIDE MACHINERY HAIDE MACHINERY HAIDE MACHINERY

HAIDE MACHINERY HAIDE MACHINERY HAIDE MACHINERY HAIDE MACHINERY HAIDE MACHINERY

HAIDE MACHINERY HAIDE MACHINERY HAIDE MACHINERY HAIDE MACHINERY HAIDE MACHINERY

ABOUT US

To provide Roll Forming Machine for global customers

Our products are mainly used in the production of steel structure industry C, Z type sandalwood, floor bearing formwork and roof, wall maintenance structure color board or insulation board; Environmental protection industry dust anode plate, cathode plate; Transportation industry high-speed guard plate, automobile cold-formed profiles; All kinds of glazed tile/press type, building floor, rolling shutter door and all kinds of cold bending forming equipment.

Haide Machinery was founded in 1996

Covers an area of more than 20000㎡

Exporting countries and regions

Our Advantages

The enterprise has strong technical force, rich manufacturing experience, we always put the interests of customers in the first place

Our Service

The company has a perfect after-sales service network, can provide you with full support from pre-sales to after-sales, to help you get the most satisfactory equipment.

Machinery Design

Tailored Machinery solutions to meet specific client needs for roll forming applications.

Installation Services

On-site installation of machinery and equipment to ensure proper setup and functionality.

Technical Support

Comprehensive after-sales support, including troubleshooting and technical assistance.

Training Programs

Training services for operators to maximize the efficiency and safety of machine operation.

Repairs Service

Scheduled maintenance services and prompt repair assistance to minimize downtime.

Components Supply

A reliable supply of spare parts and components to support ongoing operations and maintenance.

News & Blogs

With good reputation, perfect service and sufficient resources, the company has established a good reputation in the same industry.

Jul 05,2024

Haide Machinery launched a new generation of energy-saving tile press

With technological innovation as the core, Haide Machinery is committed to providing customers with more intelligent and environmentally friendly solutions

Jul 05,2024

Haide Machinery launched a new generation of energy-saving tile press

With technological innovation as the core, Haide Machinery is committed to providing customers with more intelligent and environmentally friendly solutions

Jul 05,2024

Technological innovation leads industrial upgrading, Haide machinery occupies the market opportunity

With the rapid development of the construction industry and the growing demand for green building materials, the tile press industry, as a key equipment supplier for steel structure and color steel tile production

Jul 05,2024

Beginner’s Guide to Setting Up and Operating a Roof Tile Making Machine

Roof tile manufacturing machine not only improves production efficiency and product quality, but also promotes the progress of building materials and technology, which is of great significance to meet the efficient, environmentally friendly and diversified needs of the modern construction industry.

Sales E-mail:

WhatsAPP:

Leave Message