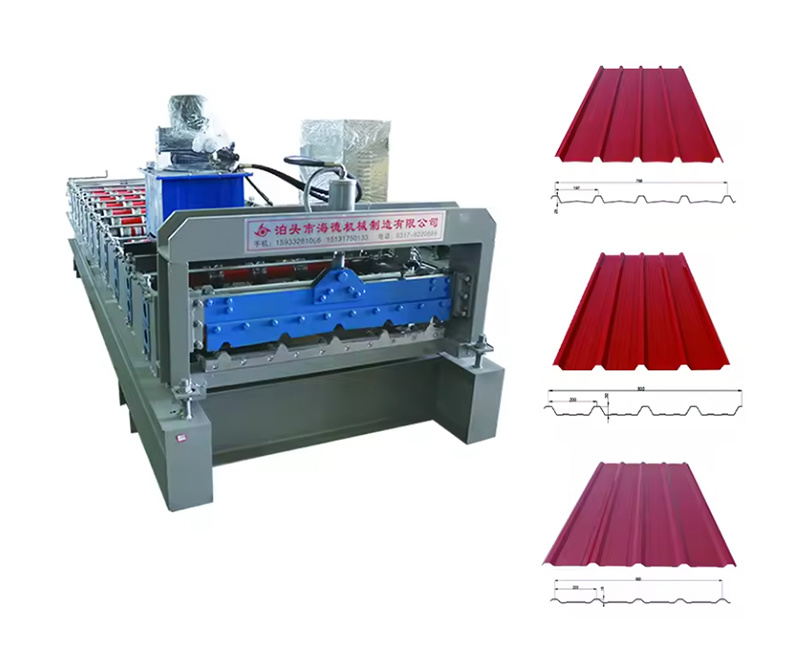

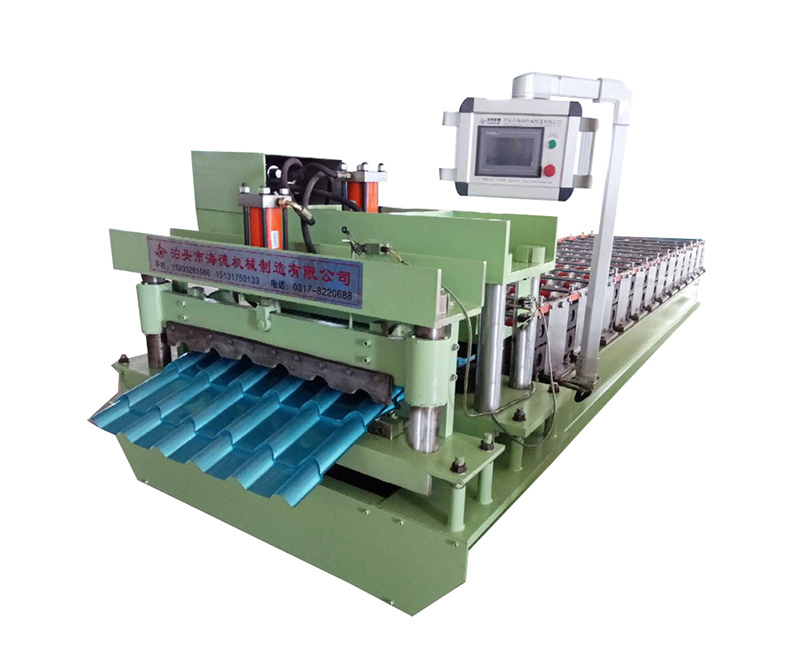

We provide Roll Forming Machine for global customers

Machine introduction

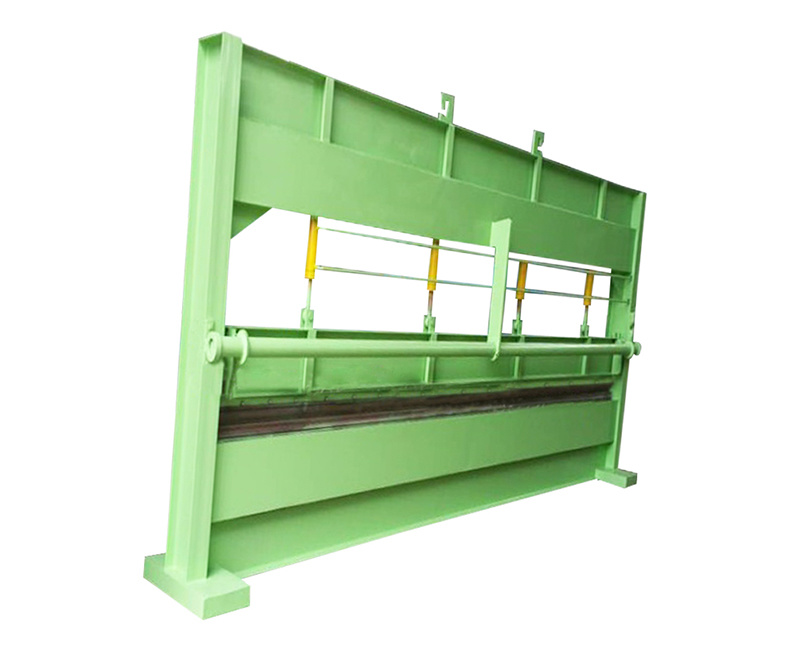

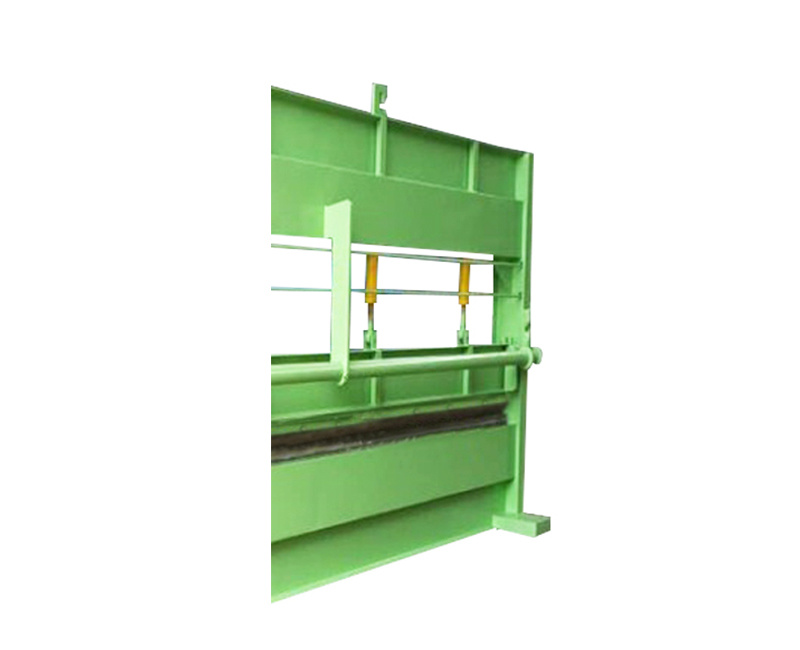

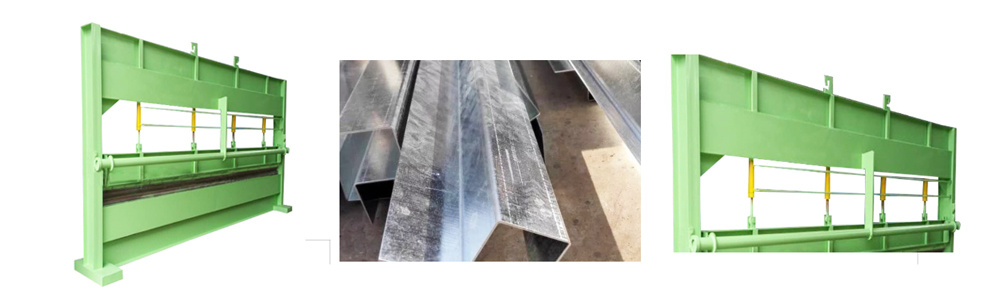

Some characteristics of the bending machine:

1. High precision: Modern bending machines usually use numerical control (CNC) technology, which can accurately control the angle and size of bending, ensuring the accuracy of products.

2. High efficiency: The use of bending machines can quickly complete batch production tasks, with a high degree of automation, reducing the time and cost of manual operations.

3. Flexibility: According to different processing requirements, the mold can be adjusted to adapt to plates of different thicknesses and materials, allowing one machine to complete various types of bending work.

4. Easy to operate: Parameter settings are made through the human-machine interface (HMI), which is simple and intuitive to operate, reducing the technical requirements for operators.

5. Safety: Equipped with various safety protection devices, such as emergency stop buttons, safety light curtains, etc., to prevent accidents during operation.

Product introduction

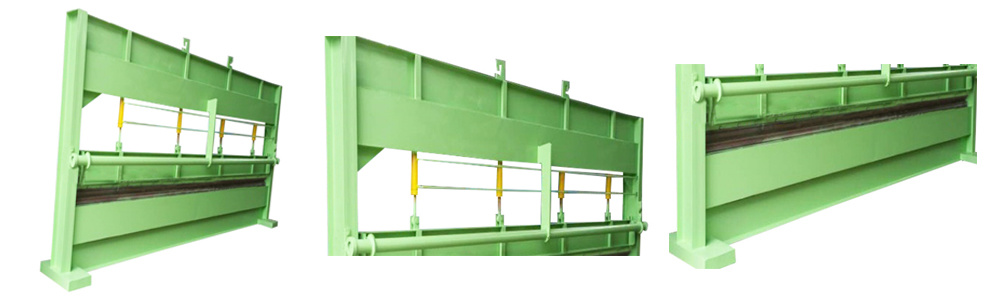

Aluminium hydraulic Sheet Roll Bending Machine 4-6m color steel sheet bending shearing machine

Operation process of bending machine

Preparation stage

1. Wear personal protective equipment: Operators need to wear necessary personal protective equipment, such as work clothes, safety shoes, goggles, etc.

2. Equipment inspection: Check whether all parts of the bending machine are intact, including molds, oil pumps, control systems, etc.

3. Preheating: Some models require a period of preheating before formal use to ensure that the equipment reaches its optimal working condition.

Startup and Debugging

1. Power on: Turn on the power switch on the control panel.

2. Start the oil pump: Press the oil pump start button to ensure that the oil pump is running normally.

3. Travel adjustment: Adjust the maximum travel of the upper and lower molds according to the thickness of the processed board, ensuring sufficient clearance between the mold and the board, usually 1 time the thickness of the board.

4. Selection of bending groove: Select the appropriate bending groove according to the thickness of the board, generally choosing a groove with a width 8-10 times the thickness of the board.

5. Rear material adjustment: Adjust the position of the rear material according to the required bending size to ensure the accuracy of the bending.

Processing operation

1. Material placement: Place the board to be processed on the workbench and adjust the positioning device to fix it in place.

2. Start bending: Press the start button or step on the foot switch to start the bending operation.

3. Monitor the machining process: Pay close attention to any abnormal situations during the machining process to ensure the positioning of the board and the normal operation of the mold.

Completion and Cleaning

1. Turn off the equipment: After completing the processing, turn off the oil pump and power switch.

2. Cleaning the workbench: Remove debris generated during processing and keep the work area clean.

3. Maintenance: Lubricate or perform other maintenance work on the equipment as needed.

Matters needing attention

-During the operation, the operator needs to maintain focus and avoid distraction or distraction.

-If any abnormal situation is found, the machine should be stopped immediately and the cause of the malfunction should be checked.

-Before operation, it is necessary to be familiar with the basic structure, performance, and usage of the bending machine.

Technical parameter

| Oil pump power | 5.5kw |

| Dimension | 6.5*1*2m |

| Weight | 2.5 ton |

| Voltage | 380v,50Hz,3Phase |

| Number oil pump | five |

| Diameter of oil pump | 100mm |

| Cutting power | 40 ton |

| Thickness of plate | ≤1.5mm |

The company has vigorously introduced the German professional roller design software COPRA, which can design various rollers according to customer needs.

Manual uncoiler

Free manual uncoiler

The coil inner diameter: φ450-550mm;

Max. outer coil diameter: φ1000mm-1250mm

The max capacity: 5T

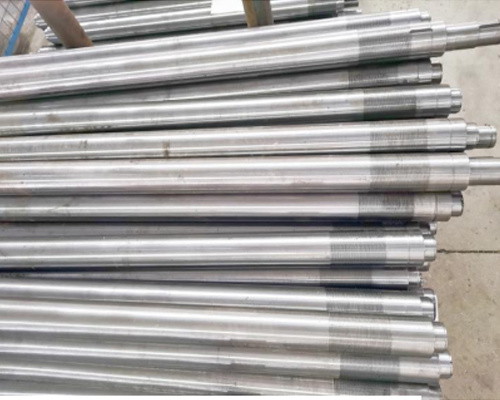

Machine shaft

All machines are finished with Cr12 rollers

Shaft hardness 58-60

Hardening depth 0.8mm

Surface roughness ra0.1m-0.35m

High quality shaft with a service life of over 15 years

Customer usage site

We designed and produced this machine for the customer based on the product drawings provided by him.

Company Profile

Our products are mainly used in the production of steel structure industry C, Z type sandalwood, floor bearing formwork and roof, wall maintenance structure color board or insulation board; Environmental protection industry dust anode plate, cathode plate; Transportation industry high-speed guard plate, automobile cold-formed profiles; All kinds of glazed tile/press type, building floor, rolling shutter door and all kinds of cold bending forming equipment, can also provide users with a variety of coil unwinding, leveling, longitudinal shear winding, transverse shear palletizing production lines.

Our Customers

We sell products to the United States, Australia, the Netherlands, Germany, Ecuador, Bolivia, Thailand, Malaysia, Indonesia, India, the Philippines, Bangladesh, Nigeria, South Africa, Ethiopia, Syria, Libya, Ghana, Sudan, Saudi Arabia, the United Arab Emirates, Turkey, Azerbaiian and other markets.

Packing

FAQs

1. Does your company can customized my needed profile?

Yes sir/Madam. Our machines are all customized according to customers' requests. Just provided me your needed profile drawing and we can give you our professional machine design solution.

2. If i don't have profile drawing, but i want to buy one machine, can you help me?

Yes sir/ Madam. If you don't have profile drawings, the solutions have:

2.1 : Provide me with your profiles' pictures ;

2.2 : Tell me your country and i will check if we sell similar / related profile machines to your there. I will recommend you related profile drawings.

2.3 : Tell me any information you have and it will be helpful for me to clear your needed profiles. and then quote you.

3. What your company advantages?

Yes sir/Madam. Our advantages have :

3.1: We are a 15 years big factory. We have abundant machine designing and making experience. We can give you the best machine solution.

3.2: We have completed production system. And more than 20 sets of CNC machines which can support lots of machine orders' making and guarantee the delivery.

3.3 : We have 20 years foreign trade exported experience. Our sellers abundant experience can guarantee you will have a pleasant purchase and use of the machine and after-sales experience. And cooperated with us , you can get more details about the machine, including those problems that you can't think of but we can think of, we can tell you to ensure that you can buy the most suitable machine for you.

3.4 : We are a golden integrity roll forming machine company.

About the after-sale services, no worries, we will responsible for you.

4. Will i receive a good machine ? Same Like I wanted to?

Yes sir/Madam. We will do the machine according to your profile drawing . About the profile drawing, we will confirm with you again before producing your machine. Then, after the machine finished, we will test the machine and guarantee the machine you received is a good machine. Because after you satisfied with the machine, and then you pay balance.

5. What is the machine minimum quantity?

One machine is okay.

6. What is your payment terms?

6.1 : We accept 30% T/T as deposit and 70% T/T as balance before shipping.

6.2 : We accept 100% L/C at sight

6.3: We accept Western Union payments.

6.4 : Other payment terms you want to pay, please let me know and i will check and reply you.

TAG:

Aluminium hydraulic Sheet Roll Bending Machine 4-6m color steel sheet bending shearing machine

Category: