We provide Roll Forming Machine for global customers

Machine introduction

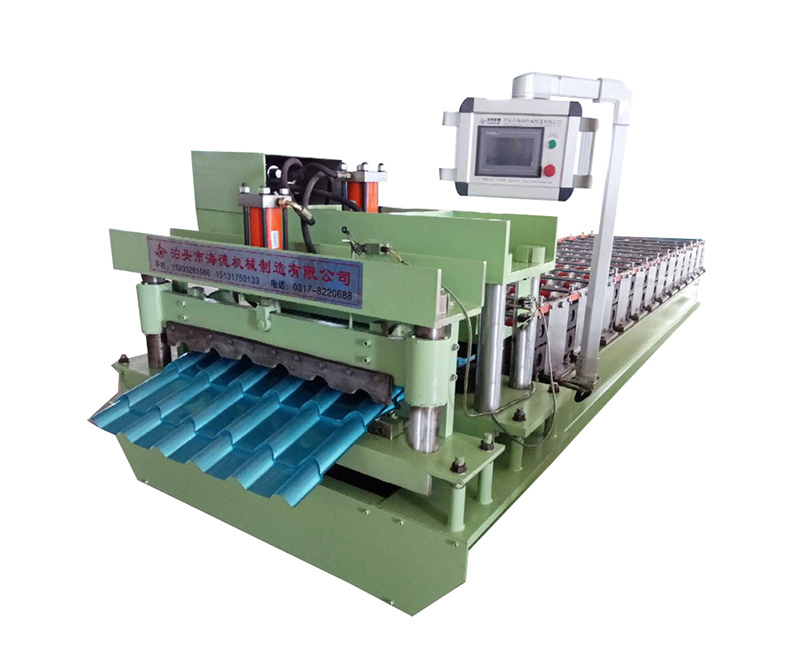

The trapezoidal roof panel single board machine is a mechanical equipment specifically used for producing trapezoidal roof panels for construction. This machine can press color steel plates or other metal sheets into roofing sheets with certain ripples or shapes. These sheets are mainly used for the roofs or walls of buildings because they have good load-bearing capacity and aesthetics, and are easy and fast to install.

Specifically, the uses of trapezoidal roof panel single board machine include but are not limited to the following:

1. Building roof: The trapezoidal panels produced can be used as roof materials for large buildings such as industrial plants, warehouses, and sports venues.

2. Wall construction: In addition to roof applications, trapezoidal panels can also be used as wall materials, especially in temporary buildings or simple houses that require quick construction.

3. Decoration and partitions: In some cases, these boards can also be used for indoor and outdoor decoration or as partitions.

4. Structural support: Due to its structural characteristics, trapezoidal panels can also provide certain structural support and can be used as part of temporary support structures during construction.

840 veneer roof roll forming machine

What is automatic IBR Roofing sheeting Machine?

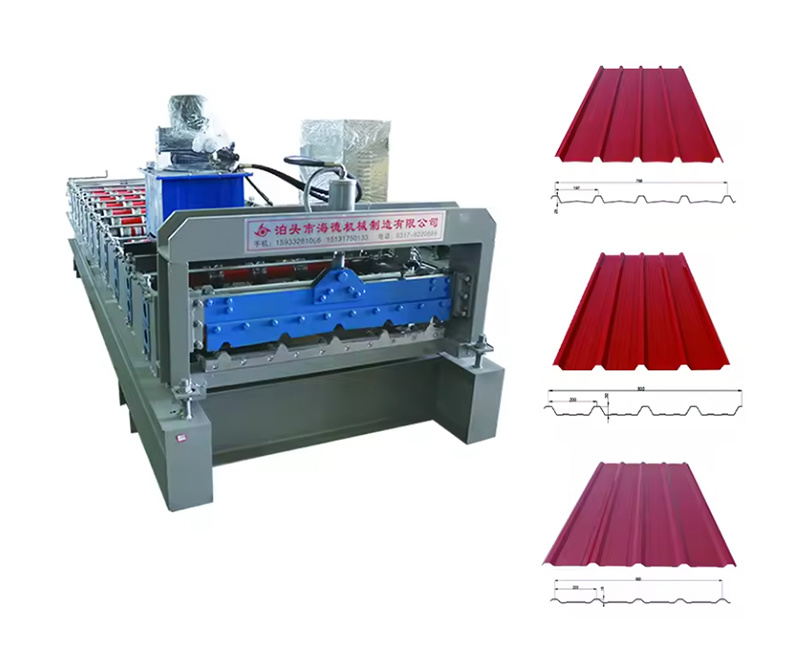

IBR tile press is a kind of mechanical equipment specially used to produce IBR (Inverted Box Rib, Chinese can be translated as "inverted box rib") type metal roof plate. IBR roof panel is a common building roof and wall material, named for its special structural design, with good waterproof, heat insulation, bearing and wind resistance performance, widely used in industrial plants, warehouses, commercial buildings, public facilities and other types of building projects.

The main features and functions of the IBR tile press include:

1. Specific shape forming: The machine is designed for the special geometry of the IBR board, which can accurately process continuous metal coils into plates with an inverted box frame structure through a series of rolling, bending and other processes. These ribs are parallel to each other and evenly distributed, forming a regular corrugated shape that ensures the strength and stability of the sheet.

2. Automation control: Modern IBR tile presses are usually equipped with advanced computer control systems to achieve automated operation of the production process. The system can accurately control parameters such as material thickness, rolling speed and shear length to ensure accurate product size and stable quality, and can be quickly adjusted to meet the production needs of different specifications.

3. Efficient production: Such equipment usually has high production efficiency and can continuously produce a large number of IBR boards in a short period of time to meet the needs of large-scale construction projects. Efficient rolling technology and rapid die change capabilities help reduce downtime and increase overall productivity.

4. Material adaptability: IBR tile press can handle different kinds of metal materials, such as galvanized steel plate, color coated steel plate, etc., suitable for different construction projects anticorrosion and decoration requirements. The equipment should have good material adaptability and be able to effectively protect the surface coating of raw materials from damage while maintaining product quality.

5. Supporting equipment: In addition to the main forming part, IBR tile press may also integrate or support auxiliary equipment such as uncoiling machine, leveling machine, hydraulic shear system, automatic palletizing device, etc., to form a complete production line, realizing the integration of raw material winding to finished product output.

How to see if IBR Edition is right for you?

Choosing the right IBR molding machine requires consideration of factors such as production capacity, tile profile, material compatibility and budget.

Product Specification

Main parts of the machine

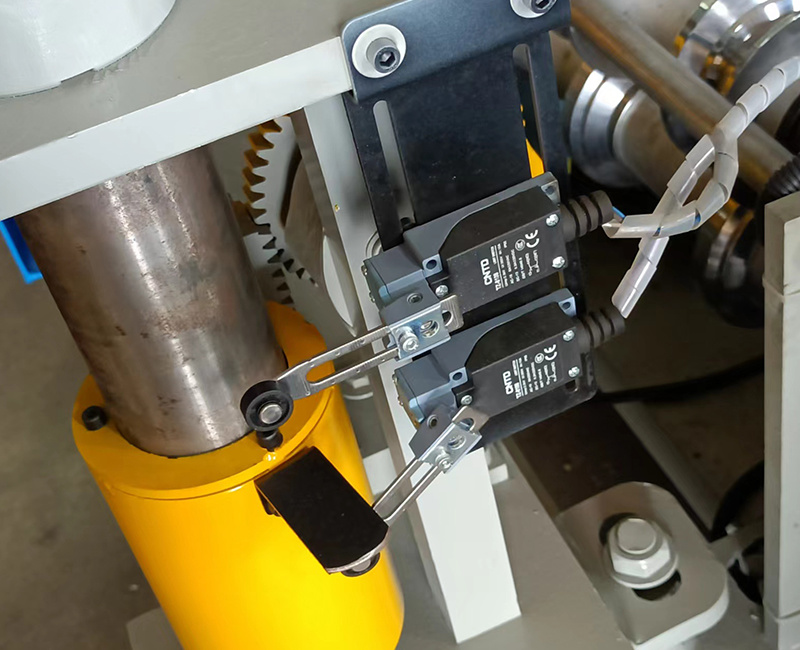

Guide and straightening: The machine includes a guide and straightening device to ensure that the metal coils are properly aligned and straightened before entering the roll forming part. This helps maintain the accuracy and consistency of the molded panel.Ensure the full flatness control from raw material feed to finished product output, thus producing high quality, high precision IBR roof panels. These measures cover all aspects from unwrapping to final quality inspection, reflecting the rigorous control of modern sheet metal processing equipment on the details of the production process.

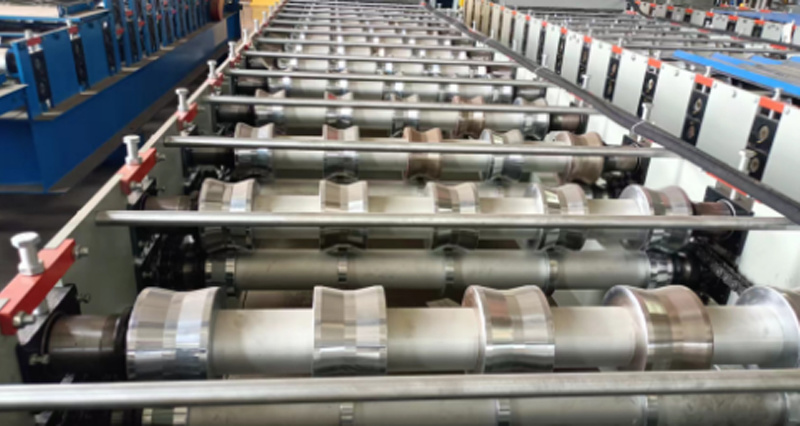

Roll forming part: The heart of the machine is the roll forming part, which consists of a series of panel rollers that gradually shape the metal coils into the desired PBR roof panel profile. Each roll forming die performs a specific bending or copying action to gradually transform the flat metal coil into the final panel shape.With its advantages of precise forming, efficient production, high material utilization rate, excellent mechanical properties, strong adaptability, high degree of automation and easy maintenance, it has become an indispensable and efficient production equipment for the metal roofing material manufacturing industry.

Cutting: Once the rolled profile is fully formed, a cutting mechanism is used to cut the rolled profile product to the desired length. This can be done using flying shears or hydraulic shears, depending on the design of the machine.

With the advantages of precise cutting, high-speed operation, automatic sizing, diversified cutting modes, synchronous cutting, safety protection and low noise and low vibration, the IBR board can achieve efficient and accurate cutting operation, which is an important part of ensuring the overall performance of the production line and product quality.

IBR roller forming machine can process the types of materials are: Steel, Aluminum

Company Profile

Our products are mainly used in the production of steel structure industry C, Z type sandalwood, floor bearing formwork and roof, wall maintenance structure color board or insulation board; Environmental protection industry dust anode plate, cathode plate; Transportation industry high-speed guard plate, automobile cold-formed profiles; All kinds of glazed tile/press type, building floor, rolling shutter door and all kinds of cold bending forming equipment, can also provide users with a variety of coil unwinding, leveling, longitudinal shear winding, transverse shear palletizing production lines.

Our Customers

We sell products to the United States, Australia, the Netherlands, Germany, Ecuador, Bolivia, Thailand, Malaysia, Indonesia, India, the Philippines, Bangladesh, Nigeria, South Africa, Ethiopia, Syria, Libya, Ghana, Sudan, Saudi Arabia, the United Arab Emirates, Turkey, Azerbaiian and other markets.

Packing

FAQs

1. Does your company can customized my needed profile?

Yes sir/Madam. Our machines are all customized according to customers' requests. Just provided me your needed profile drawing and we can give you our professional machine design solution.

2. If i don't have profile drawing, but i want to buy one machine, can you help me?

Yes sir/ Madam. If you don't have profile drawings, the solutions have:

2.1 : Provide me with your profiles' pictures ;

2.2 : Tell me your country and i will check if we sell similar / related profile machines to your there. I will recommend you related profile drawings.

2.3 : Tell me any information you have and it will be helpful for me to clear your needed profiles. and then quote you.

3. What your company advantages?

Yes sir/Madam. Our advantages have :

3.1: We are a 15 years big factory. We have abundant machine designing and making experience. We can give you the best machine solution.

3.2: We have completed production system. And more than 20 sets of CNC machines which can support lots of machine orders' making and guarantee the delivery.

3.3 : We have 20 years foreign trade exported experience. Our sellers abundant experience can guarantee you will have a pleasant purchase and use of the machine and after-sales experience. And cooperated with us , you can get more details about the machine, including those problems that you can't think of but we can think of, we can tell you to ensure that you can buy the most suitable machine for you.

3.4 : We are a golden integrity roll forming machine company.

About the after-sale services, no worries, we will responsible for you.

4. Will i receive a good machine ? Same Like I wanted to?

Yes sir/Madam. We will do the machine according to your profile drawing . About the profile drawing, we will confirm with you again before producing your machine. Then, after the machine finished, we will test the machine and guarantee the machine you received is a good machine. Because after you satisfied with the machine, and then you pay balance.

5. What is the machine minimum quantity?

One machine is okay.

6. What is your payment terms?

6.1 : We accept 30% T/T as deposit and 70% T/T as balance before shipping.

6.2 : We accept 100% L/C at sight

6.3: We accept Western Union payments.

6.4 : Other payment terms you want to pay, please let me know and i will check and reply you.

TAG:

840 veneer roof roll forming machine

Category: