We provide Roll Forming Machine for global customers

Machine introduction

characteristic:

1. High precision:

-The strip leveling machine can accurately control the width and thickness of the product, ensuring that the processed material has good straightness and flatness.

2. Multifunctionality:

-The equipment can process coils of different materials (such as stainless steel, copper, aluminum, etc.) and thicknesses, with strong adaptability.

3. High degree of automation:

-It is usually equipped with advanced control systems that can achieve functions such as automatic feeding, cutting to length, and automatic unloading, reducing manual operations and improving production efficiency.

4. Efficient and energy-saving:

-When designing, we will consider the effective utilization of energy and adopt energy-saving technologies to reduce energy consumption.

5. Easy to operate:

-User friendly interface, simple operation, and easy maintenance.

6. Good stability:

-Stable structure, smooth operation, and the ability to maintain good working condition for a long time.

Product introduction

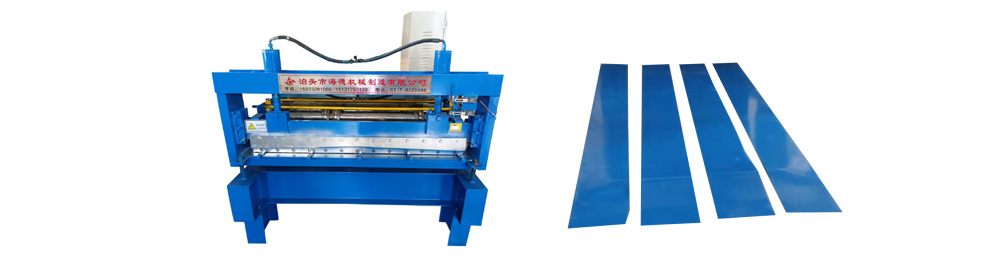

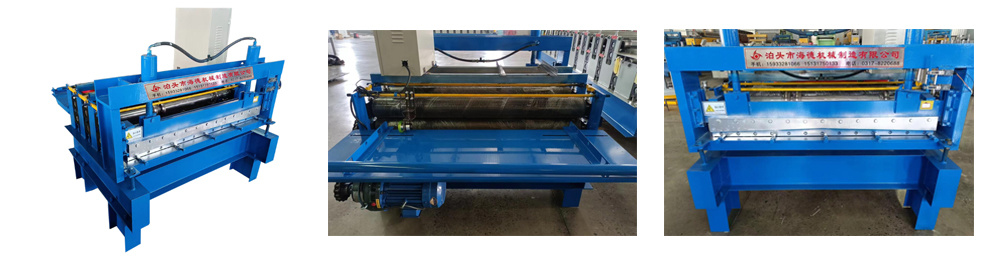

Steel profile strip slitting machine levelling and cutting machine

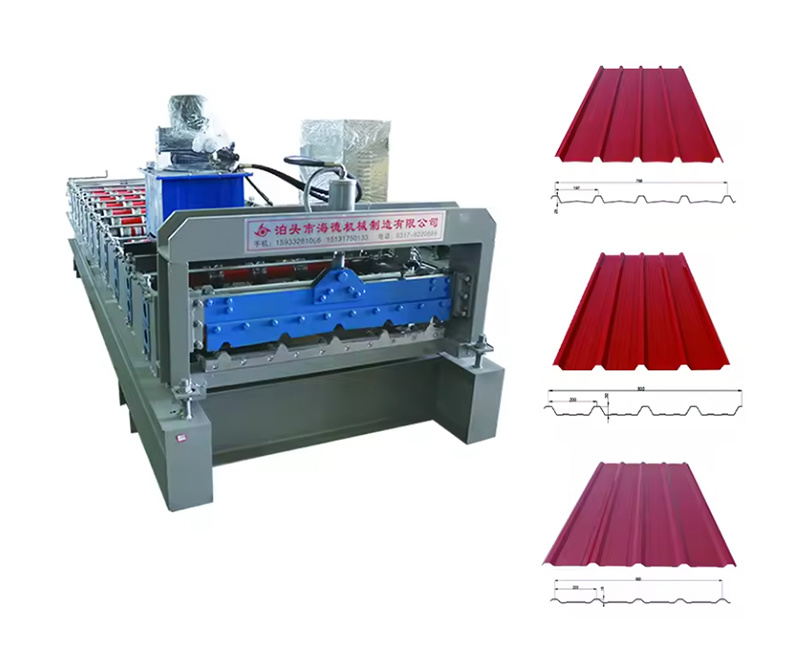

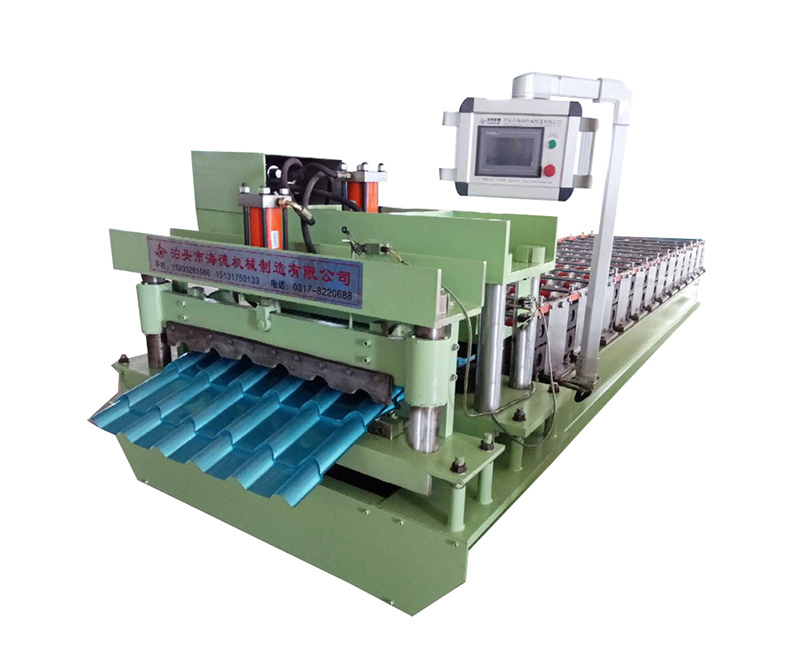

Suppliers of various types of support plates

1. Loading:

-The coil is loaded onto the loading rack of the machine.

2. Open book:

-Unfold the coil into a continuous strip using an unwinding mechanism, such as a hydraulic or electric unwinding machine.

3. Guiding positioning:

-The use of guiding devices ensures that the material advances along the correct path, typically including guide rollers and lateral adjustment devices to control the position of the material.

4. Pre straightening:

-Before entering the main straightening section, a pre straightening process may be required to initially eliminate bending in the coil.

5. Straightening:

-This is the most crucial part of the entire process. The material passes through a series of straightening roller groups, which apply force to the material according to the set pressure to eliminate defects such as wave shapes and distortions in the material.

-The number and spacing of straightening rollers can be adjusted according to the thickness and hardness of different materials.

6. Flatness:

-After straightening, the material may have some slight deformation, so it is necessary to further improve the surface quality through a leveling mechanism.

-Flattening can be achieved through the pressure between multiple rollers, making the material surface smoother and smoother.

7. Cutting/Slitting:

-If it is necessary to divide the material into strips of a specified width, it can be done through cutting or slitting mechanisms.

-Slitting machines are usually equipped with precision cutting tool systems to ensure cutting accuracy.

8. Roll up:

-The processed material is rolled back onto a new reel, ready for subsequent processing or packaging.

9. Quality inspection:

-Throughout the entire process, visual inspection systems or other quality control devices may also be equipped to monitor the quality and performance of the product.

10. Unloading:

-The final step is to unload the finished product from the machine and perform necessary packaging and storage.

Technical parameter

| Number of leveling rollers | 6 on top and 7 on bottom, a total of 13 spindles |

| Leveling axis diameter | 100mm |

| middle plate thickness | 30mm (customizable) |

| Host power | 3kw |

| hydraulic station power | 3kw (customizable) |

| Transmission method | Wall mounted gear transmission |

| Cutting method | Fully automatic CNC counting, with frequency conversion, accurate counting |

The company has vigorously introduced the German professional roller design software COPRA, which can design various rollers according to customer needs.

Manual uncoiler

Free manual uncoiler

The coil inner diameter: φ450-550mm;

Max. outer coil diameter: φ1000mm-1250mm

The max capacity: 5T

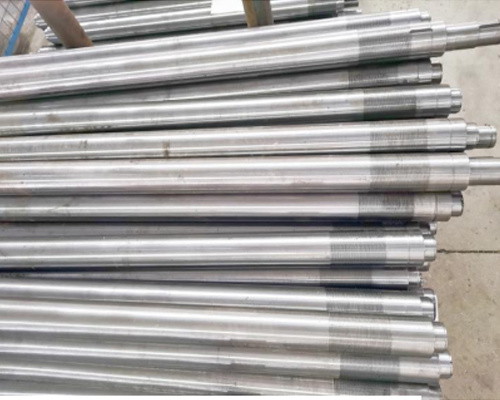

Machine shaft

All machines are finished with Cr12 rollers

Shaft hardness 58-60

Hardening depth 0.8mm

Surface roughness ra0.1m-0.35m

High quality shaft with a service life of over 15 years

Customer usage site

We designed and produced this machine for the customer based on the product drawings provided by him.

Company Profile

Our products are mainly used in the production of steel structure industry C, Z type sandalwood, floor bearing formwork and roof, wall maintenance structure color board or insulation board; Environmental protection industry dust anode plate, cathode plate; Transportation industry high-speed guard plate, automobile cold-formed profiles; All kinds of glazed tile/press type, building floor, rolling shutter door and all kinds of cold bending forming equipment, can also provide users with a variety of coil unwinding, leveling, longitudinal shear winding, transverse shear palletizing production lines.

Our Customers

We sell products to the United States, Australia, the Netherlands, Germany, Ecuador, Bolivia, Thailand, Malaysia, Indonesia, India, the Philippines, Bangladesh, Nigeria, South Africa, Ethiopia, Syria, Libya, Ghana, Sudan, Saudi Arabia, the United Arab Emirates, Turkey, Azerbaiian and other markets.

Packing

FAQs

1. Does your company can customized my needed profile?

Yes sir/Madam. Our machines are all customized according to customers' requests. Just provided me your needed profile drawing and we can give you our professional machine design solution.

2. If i don't have profile drawing, but i want to buy one machine, can you help me?

Yes sir/ Madam. If you don't have profile drawings, the solutions have:

2.1 : Provide me with your profiles' pictures ;

2.2 : Tell me your country and i will check if we sell similar / related profile machines to your there. I will recommend you related profile drawings.

2.3 : Tell me any information you have and it will be helpful for me to clear your needed profiles. and then quote you.

3. What your company advantages?

Yes sir/Madam. Our advantages have :

3.1: We are a 15 years big factory. We have abundant machine designing and making experience. We can give you the best machine solution.

3.2: We have completed production system. And more than 20 sets of CNC machines which can support lots of machine orders' making and guarantee the delivery.

3.3 : We have 20 years foreign trade exported experience. Our sellers abundant experience can guarantee you will have a pleasant purchase and use of the machine and after-sales experience. And cooperated with us , you can get more details about the machine, including those problems that you can't think of but we can think of, we can tell you to ensure that you can buy the most suitable machine for you.

3.4 : We are a golden integrity roll forming machine company.

About the after-sale services, no worries, we will responsible for you.

4. Will i receive a good machine ? Same Like I wanted to?

Yes sir/Madam. We will do the machine according to your profile drawing . About the profile drawing, we will confirm with you again before producing your machine. Then, after the machine finished, we will test the machine and guarantee the machine you received is a good machine. Because after you satisfied with the machine, and then you pay balance.

5. What is the machine minimum quantity?

One machine is okay.

6. What is your payment terms?

6.1 : We accept 30% T/T as deposit and 70% T/T as balance before shipping.

6.2 : We accept 100% L/C at sight

6.3: We accept Western Union payments.

6.4 : Other payment terms you want to pay, please let me know and i will check and reply you.

TAG:

Steel profile strip slitting machine levelling and cutting machine

Category: