We provide Roll Forming Machine for global customers

Machine introduction

Roller shutter door locking edge machine is a mechanical equipment specifically used for processing and installing edge components of roller shutter doors.

This machine is mainly used in the following areas:

1. Aesthetics and Protection: The locking edge can not only improve the overall appearance quality of the rolling shutter door, but also play a certain protective role, such as dust and water resistance.

2. Enhance security: For some applications that require higher security levels, such as banks, vaults, etc., roller shutter doors processed by edge locking machines can better resist illegal intrusion attempts.

Overall, the roller shutter door locking edge machine is one of the essential equipment for producing high-quality and high safety roller shutter doors.

Product introduction

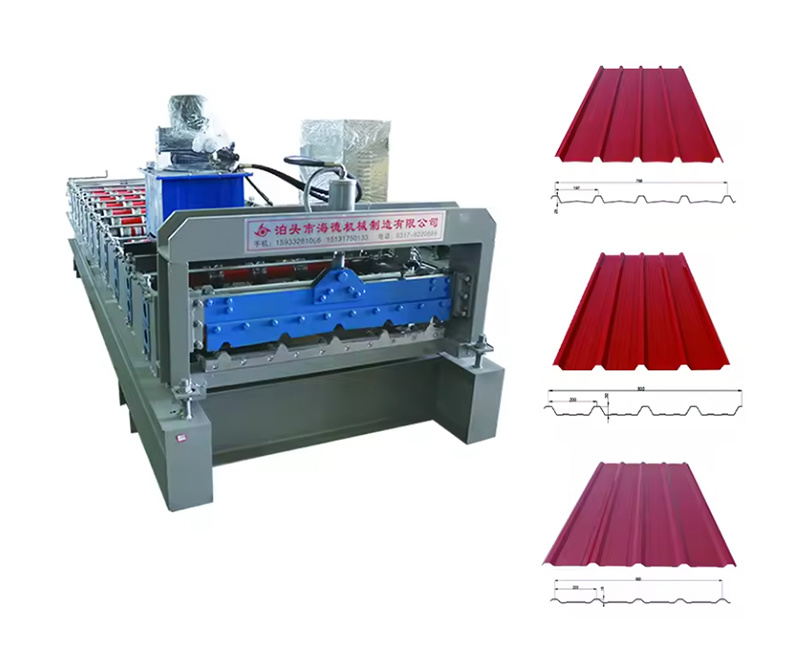

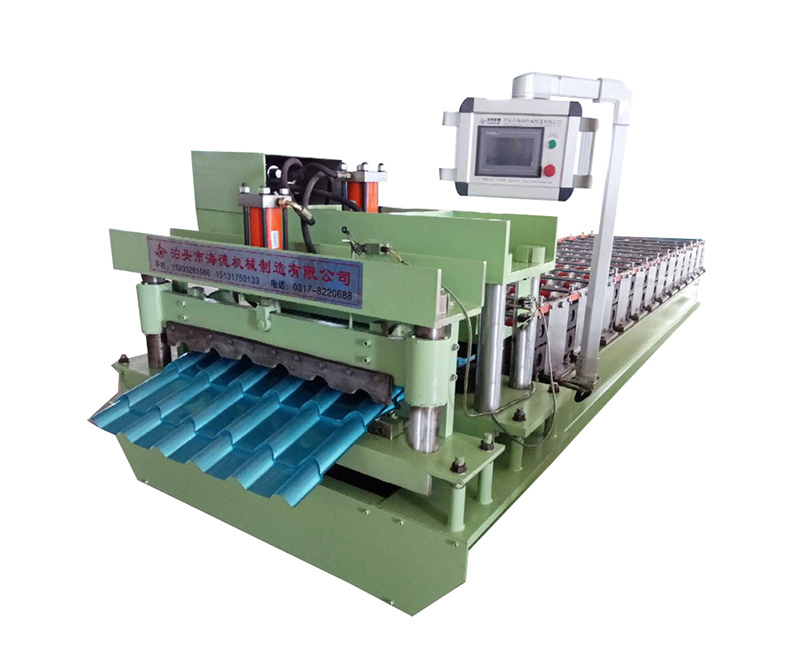

Rolling shutter door tile press machine

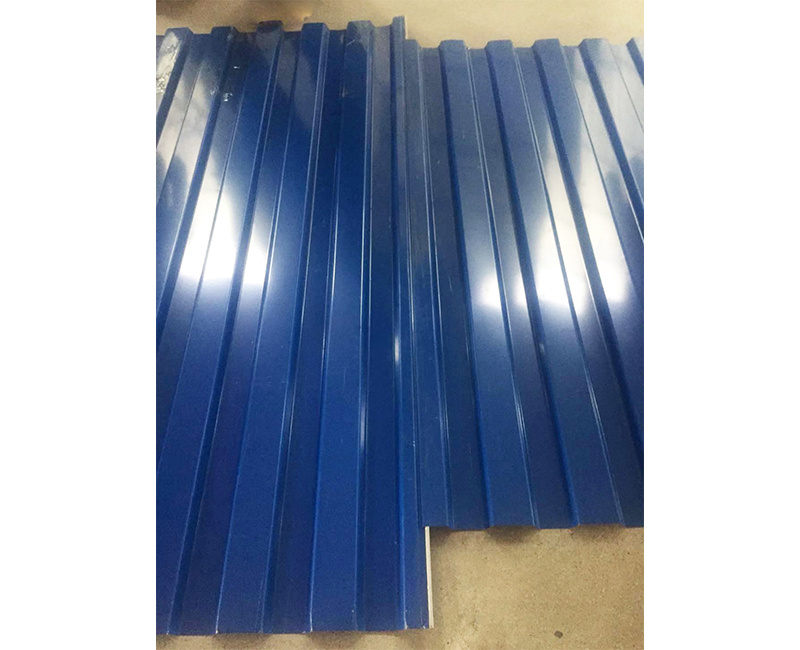

Suppliers of various types of support plates

Instructions for using the roller shutter door locking edge machine

Operation steps

(1) Adopting a longitudinal groove type threading mechanism, when threading, simply insert the suture thread along the straight groove to lead the thread to the clamping device. The operation is very simple and there will be no errors.

(2) The opening action of the clamping board adopts a linkage method with the lifting of the presser foot, which facilitates the threading action.

(3) A lead device is installed at the threading position of the lower bending needle, making the complex threading action of the lower bending needle in the overlock sewing machine easier.

(4) By using an external adjustment method with a needle spacing adjustment disc, the length of the needle spacing can also be adjusted from the outside during the sewing process.

Technical parameter

| Working voltage | 220V |

| Rated frequency | 50-60HZ |

| Maximum plate thickness | 0.60mm Rated speed |

| Motor output power | 0.74KW |

| Rated speed of motor | 330r/min |

| Dimensions | 470mm * 390mm * 310mm |

| Weight | 33Kg |

Rolling shutter door tile press machine

The company has vigorously introduced the German professional roller design software COPRA, which can design various rollers according to customer needs.

Manual uncoiler

Free manual uncoiler

The coil inner diameter: φ450-550mm;

Max. outer coil diameter: φ1000mm-1250mm

The max capacity: 5T

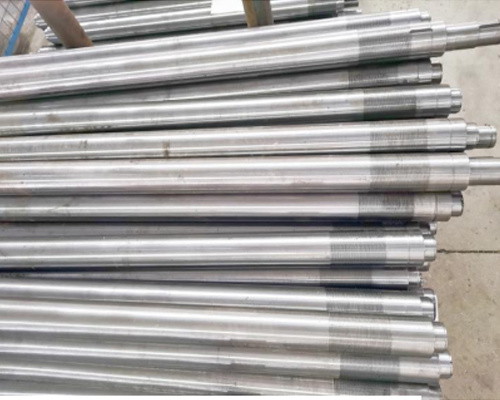

Machine shaft

All machines are finished with Cr12 rollers

Shaft hardness 58-60

Hardening depth 0.8mm

Surface roughness ra0.1m-0.35m

High quality shaft with a service life of over 15 years

Customer usage site

We designed and produced this machine for the customer based on the product drawings provided by him.

Company Profile

Our products are mainly used in the production of steel structure industry C, Z type sandalwood, floor bearing formwork and roof, wall maintenance structure color board or insulation board; Environmental protection industry dust anode plate, cathode plate; Transportation industry high-speed guard plate, automobile cold-formed profiles; All kinds of glazed tile/press type, building floor, rolling shutter door and all kinds of cold bending forming equipment, can also provide users with a variety of coil unwinding, leveling, longitudinal shear winding, transverse shear palletizing production lines.

Our Customers

We sell products to the United States, Australia, the Netherlands, Germany, Ecuador, Bolivia, Thailand, Malaysia, Indonesia, India, the Philippines, Bangladesh, Nigeria, South Africa, Ethiopia, Syria, Libya, Ghana, Sudan, Saudi Arabia, the United Arab Emirates, Turkey, Azerbaiian and other markets.

Packing

FAQs

1. Does your company can customized my needed profile?

Yes sir/Madam. Our machines are all customized according to customers' requests. Just provided me your needed profile drawing and we can give you our professional machine design solution.

2. If i don't have profile drawing, but i want to buy one machine, can you help me?

Yes sir/ Madam. If you don't have profile drawings, the solutions have:

2.1 : Provide me with your profiles' pictures ;

2.2 : Tell me your country and i will check if we sell similar / related profile machines to your there. I will recommend you related profile drawings.

2.3 : Tell me any information you have and it will be helpful for me to clear your needed profiles. and then quote you.

3. What your company advantages?

Yes sir/Madam. Our advantages have :

3.1: We are a 15 years big factory. We have abundant machine designing and making experience. We can give you the best machine solution.

3.2: We have completed production system. And more than 20 sets of CNC machines which can support lots of machine orders' making and guarantee the delivery.

3.3 : We have 20 years foreign trade exported experience. Our sellers abundant experience can guarantee you will have a pleasant purchase and use of the machine and after-sales experience. And cooperated with us , you can get more details about the machine, including those problems that you can't think of but we can think of, we can tell you to ensure that you can buy the most suitable machine for you.

3.4 : We are a golden integrity roll forming machine company.

About the after-sale services, no worries, we will responsible for you.

4. Will i receive a good machine ? Same Like I wanted to?

Yes sir/Madam. We will do the machine according to your profile drawing . About the profile drawing, we will confirm with you again before producing your machine. Then, after the machine finished, we will test the machine and guarantee the machine you received is a good machine. Because after you satisfied with the machine, and then you pay balance.

5. What is the machine minimum quantity?

One machine is okay.

6. What is your payment terms?

6.1 : We accept 30% T/T as deposit and 70% T/T as balance before shipping.

6.2 : We accept 100% L/C at sight

6.3: We accept Western Union payments.

6.4 : Other payment terms you want to pay, please let me know and i will check and reply you.

TAG:

Rolling shutter door tile press machine

Category: